DESOFIN™

General:

Desofin is an additive for grain refining and deoxydation of yellow brass. It is recommended for permanent mold casting – both gravity casting and low and high pressure die casting. Desofin is also recommended for sand and shell molding. Use of Desofin enhances castability and reduces and usually eliminates defects in casting caused by impeded linear shrinkage, hot-tearing and stress cracking.

Desofin does not contain arsenic, titanium, beryllium or cesium.

Alloy Requirements:

Best casting results will occur with clean yellow brass ingot. The basic brass must be free of inclusions which are identified by a visual check of the polished surface.

The following alloy composition (shown as percentage) is recommended:

Cu 59.5 to 61.5

Pb 0 to 3.0

Al 0.5 to 0.7

Ni 1

Sn + Fe 0.5 max.

Mn 0.02 max.

Si 0.02 max.

Zn Balance

Desofin has been used to lower the casting temperature and increase the castability and fluidity of aluminum bronze, red brass and tin bronze. It is not designed as a grain refiner for these materials.

Form:

Desofin is prepared in 50 gram capsules. Custom capsule weights are available.

Desofin is normally sold in 10 kgs or 25 kgs lots.

Consumption:

200 grams of Desofin is recommended per metric ton of melted brass to be inoculated. This equates to one 50 gram capsule for each 250 kgs of melted brass.

Method of Use:

As a safety precaution, care must be taken to preheat the Desofin capsules on the furnace rim, shelf, etc. so they are free of any moisture.

Any adjustments to the aluminum or zinc content of the melt should be made prior to adding Desofin. The surface of the liquid metal should be reasonably free of slag.

Desofin should be added to melt by immersing the capsules about 50 cm below the liquid metal surface using a bell shaped plunger.

Attributes:

Alloy treated with Desofin will have the following attributes:

a. improved fluidity of the metal to be cast.

b. lower casting temperatures are possible depending on the size of the part to be cast and the type of mould used. Generally between 940 and 980 degrees C for Be-Cu molds.

Lower temperatures are possible with iron or steel molds.

c. better castability

d. cracking tendencies of the parts to be cast are greatly reduced; and most often cracks are eliminated.

e. sinks are greatly reduced

f. Pb is more uniformly distributed in the fine grain structure.

Savings:

The following savings should be expected when using Desofin.

a. savings over the price of purchasing fine grained ingot.

b. significant reduction of casting scrap.

c. reduction in finishing and rework costs result from better cast surfaces.

d. energy savings resulting from lower casting temperature.

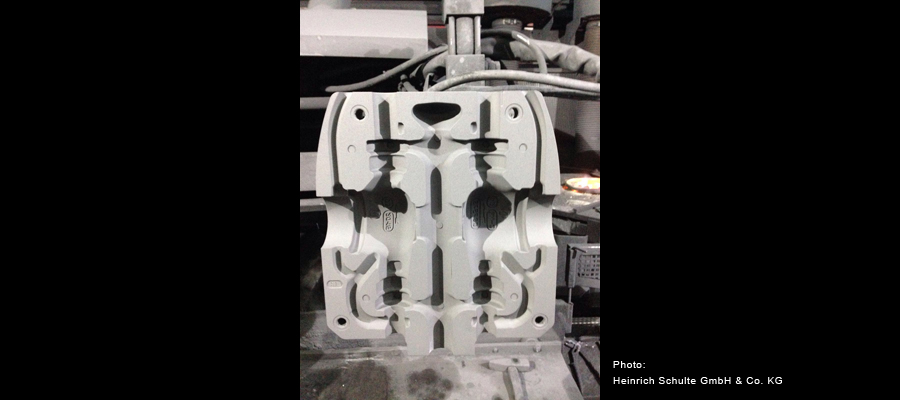

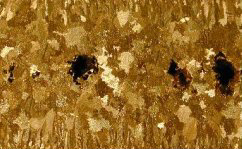

Cross Sections:

Without Desofin

With Desofin